Nobell Foods

Fifty Years partners with Nobell Foods to unlock the power of plants for animal-free cheese

If it took 10 gallons of gas to drive a mile, would you use your car much? If a latte cost $1,000, would you buy any? It would be ludicrous to waste such large amounts of resources to get such small returns. Yet this tremendous waste underpins our entire food supply chain.

Animals are terribly inefficient at converting raw materials into food -- it's simply not what they were born to do. To create a single pound of chicken we need to give the birds 2 pounds of feed. A single pound of beef requires 6 pounds of feed. And a single gallon of milk requires a whopping 6 pounds of feed and over 1,000 gallons of water!1

The dismal food returns from livestock is not a new revelation. Winston Churchill knew almost a century ago that one day we would need to “escape the absurdity of growing a whole chicken in order to eat the breast or wing.” The absurdity of this method is heightened by the fact that we know converting raw resources into animal-derived food comes with the byproduct of climate changing greenhouse gases, ecosystem collapse, and the destruction of natural resources such as usable land and freshwater. A full 2% of GHG emissions come from dairy cows alone.

Thankfully, Winston had a solution for us.

To get the chicken breast or wing, we simply need to be “growing these parts separately under a suitable medium.” More simply, we just need to culture it. While this obviously wasn’t possible in the 1930s, we’re finally living in an age where we can leverage the tools of bioengineering to grow many of these animal products directly, without the animals. By taking tighter control of the production methods, we can optimize for output and resource efficiency in a way we simply can’t if we try to optimize a whole cow or bird.

With the last decade’s biotech explosion came companies that leverage these advances to create animal-free products that are identical to those made from animals. Upside Foods cultures animal cells to make meat that feels and tastes like it came from a butcher. Vitro Labs creates lab-grown leather by borrowing tissue engineering methods from regenerative medicine and applying them to cow cells. Geltor creates gelatin and collagen the same way we brew beer, replacing cows with yeast. These companies have already removed the horrible byproducts that plague animal agriculture. And they have the tools to iterate on the method to improve yield and reduce costs, eventually making their products economically competitive with animal products.

But there is one animal-derived product that any vegan reading this knows we have not yet nailed: cheese.

Plant-based cheese alternatives have not lived up to their animal-based counterparts. No one has achieved the same flavor, consistency, and mouth feel of dairy cheese. Plant-based cheeseburgers are gummy; plant-based grilled cheeses taste like cardboard; and plant-based pizzas don’t have instagram-worthy cheese pulls.

The reason these plant-based cheeses fail to deliver is because cow milk is a complex mixture of proteins and metabolites, many of which can only be created by mammals. The key ingredient that gives cheese its tasty, melty, and stretchy properties is a single biomolecule that makes up about 80% of the protein in cow’s milk -- casein.

For a growing calf, the casein in milk provides essential amino acids, carbohydrates, and minerals. For a growing block of cheese, the casein protein is what gets denatured to give it its characteristic consistency.

Proteins have a 3 dimensional structure that gives each one its characteristic properties. Under some stress like heat or acidification, proteins undergo a process called denaturation (as shown below) that destroys this shape. Denatured proteins tend to tangle into solid masses, losing their intended function but creating a new substance. Denaturation is the reason why eggs turn hard when boiled, why Alzheimer’s patients lose neural function, and -- for cheese -- why some milk and a little lemon juice form the curds that begin the cheesemaking process.

Casein also gives cheese many of its characteristic flavor notes. This happens because microorganisms like fungi and bacteria break down these molecules to be used in their metabolism. As they break down denatured casein, they leave new molecules and smaller proteins that impart new flavors to the cheese. The aging processes that make a variety of cheeses we love are in large part due to microbial digestion of casein.

Casein has been completely left out of plant-based cheeses -- meaning there is no casein to be denatured into textures we crave or broken down into flavor compounds we love.

Traditionally, if we wanted to obtain animal protein from non-animal sources, we could splice the gene into a microorganism such as Saccharomyces cerevisiae -- more affectionately known as brewers yeast -- and use our millennia worth of expertise in fermentation to produce it. Yeast has been a protein expression workhorse since the beginning of biotechnology -- they are cheap to grow, easy to work with, and there are a ton of tools to engineer them. We’ve become experts at inserting genes that encode commodity proteins into yeast, putting them into bioreactors, and thereby synthesizing a protein of interest overnight.

But engineering these tiny fungi is the easy part. In a test-tube, fermenting a protein like casein is no problem because we can easily control such a small environment. But scaling this up to batch reactors the size of swimming pools is exceedingly difficult. At this size, it’s nearly impossible to keep the tank sterile, maintain oxygen levels throughout the reactor, dilute toxic byproducts, and keep nutrients mixing without killing the yeast. The stress of such inefficient reactors imposes pressure on the yeast that kick-starts Darwinian evolution -- they dramatically mutate the foreign gene until it’s no longer expressed in a bid to redirect resources toward surviving this inhospitable environment. Because of this, engineering yeast at small scale for casein production is easy but scaling up production of that yeast-made casein is exceedingly difficult to do economically.

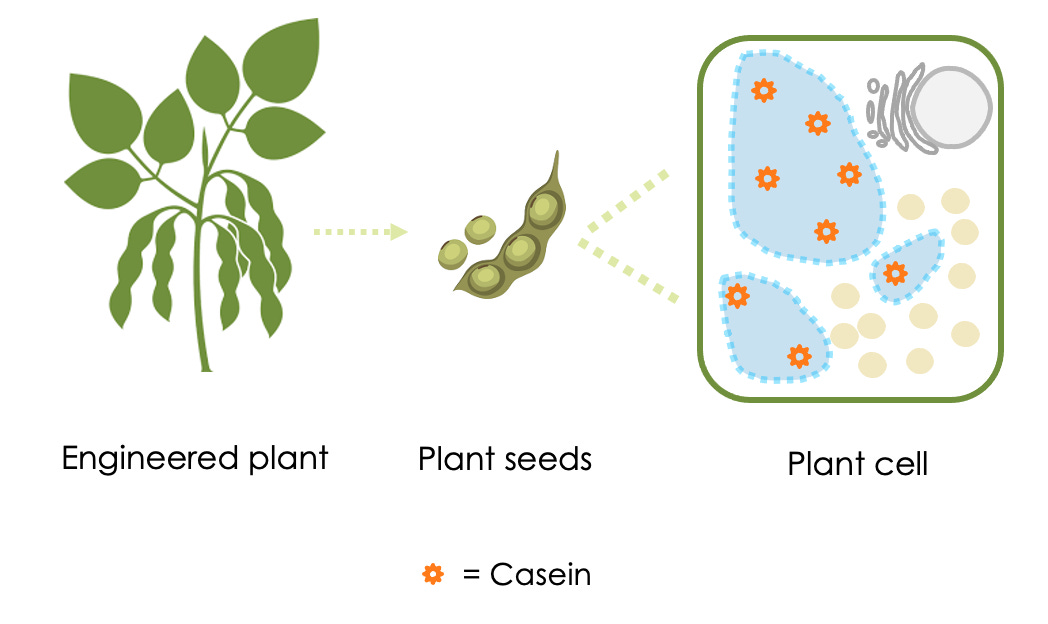

There are other expression hosts with better ability to scale but these have yet to be widely adopted since they have their own challenges. Engineered plants exemplify this trade-off. Scaling a plant is as simple as can be. If you can generate a plant that expresses casein, you simply need to plant its seeds to scale production -- whether it's a single plant on a windowsill, a handful of them in a greenhouse, or hundreds of thousands of them in a field, growing them is the same process.

Unfortunately, engineering plants to express a commodity protein at high levels is an extremely difficult task -- we simply do not have the same genetic engineering toolbox for plants that we have for yeast. Because of this, engineering plants for casein production is extremely difficult, even though they would be so much easier to scale economically.

Enter Nobell Foods, who have unlocked the secrets of plant engineering to cheaply, efficiently, and sustainably produce casein without the animal. The team is led by founder and CEO Magi Richani, who became a world-class project manager during her time managing large projects at Shell. There, she became keenly aware of the environmental challenges facing the world and was galvanized to shift her focus to fixing them. Magi has brought together a team of world experts in the fields of Food Science, Agronomy, and Plant Biology, including Viviane Lanquar, a plant biology PhD who led the discovery platform that discovered the egg-like protein that makes JUST’s product.

With a set of proprietary technologies that span 15 patent filings, Nobell Foods has spliced the casein gene into soy plants. Leveraging their unique biology, these plants were engineered to generate large quantities of casein and conveniently store the protein in the soybean. No need for dairy cows, no need for fermentation, just a single, well-established crop that creates the vital protein that makes delicious cheese.

Nobell Foods has already developed a method to take these soybeans, extract the casein, and turn it into a plant-based cheese product. They plan to take on the US cheese market by creating plant-based alternatives to mozzarella, for stretchy and gooey pizza cheese, and cheddar, for flavorful fast food cheese.

Most importantly, their cheese is already economically competitive with cow-derived cheeses. Humans are excellent at growing soybeans, making Nobell Food’s casein much easier to scale than either dairy cows or fermentation. The casein from their soybeans is significantly cheaper to produce than casein from cows and is nearly 95% cheaper than established fermentation methods. More importantly, the casein is extremely resource efficient -- a bushel of Nobell’s soybeans produces nearly 10x more cheese than a bushel of feed given to a dairy cow to produce milk.

And the Nobell Foods vision doesn’t stop there. Magi sees the technology they’ve developed to get soy plants to express casein as the first step in turning plants into a suitable expression host, on par with brewers yeast, algae, and E. coli. Using the unbeatable technoeconomics and scaling path that plants afford, Nobell plans to make a suite of plant-based food products that are traditionally derived from animals.

In a world where Nobell Food succeeds, the cruel, inefficient, and unsustainable use of animals as production platforms to make proteins is a thing of the past. Instead, carbon negative plants will make all the dairy proteins we need. And to get these proteins into the hands of every person on the planet simply requires growing crops the way we have been for millennia.

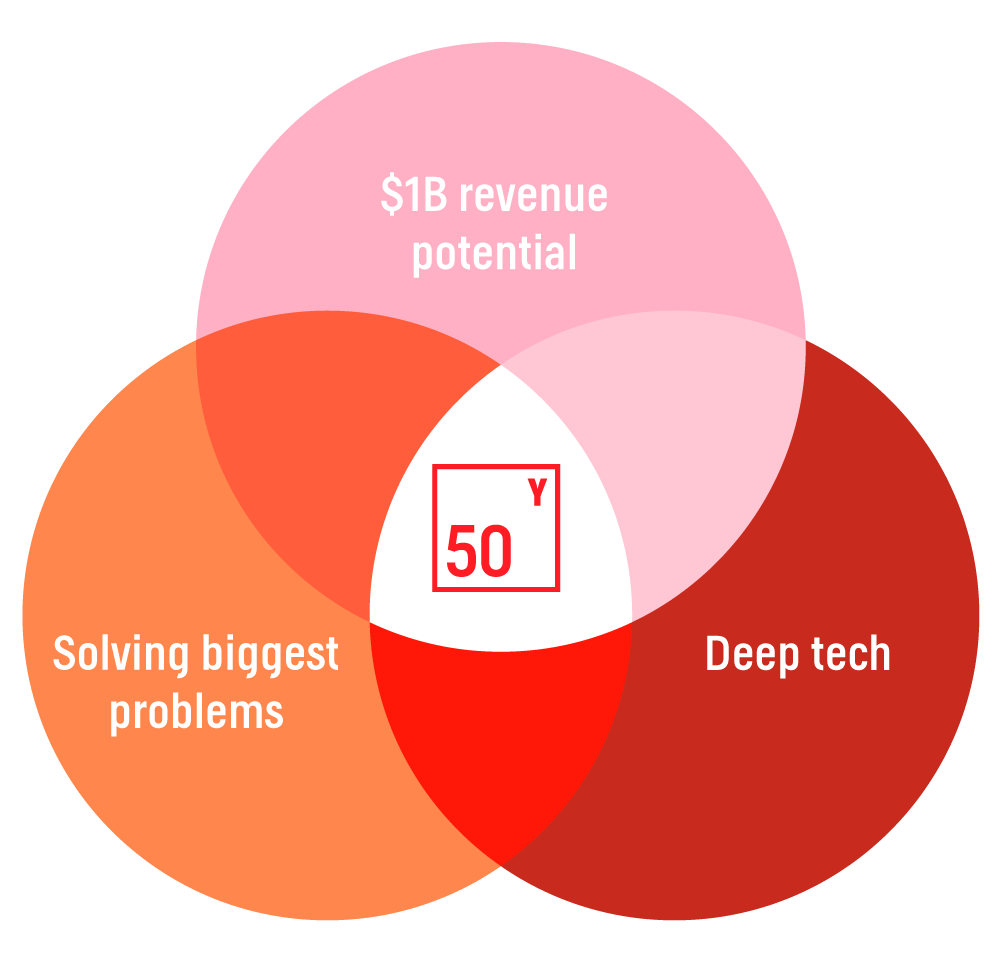

At Fifty Years, our sweet spot is supporting founders at the earliest stages building deep tech companies that can generate huge financial outcomes and create massive positive impact.

Deep Tech: The Nobell Foods team has invented a number of technologies that open new avenues to plant engineering. This suite of tools will enable them to use plants to make a number of food products typically only made from animals.

$1B yearly revenue potential: By leveraging the technoeconomics and scale of plant crops, Nobell Foods has created a less expensive way of producing animal proteins compared to both animal-based production methods and fermentation. While plant-based cheese has a 1% market share today, Nobell paves the path to plant-based cheese having 99% market share in the future.

Massive positive societal impact: The Nobell Foods platform removes animals from our food supply chain, thereby ending animal suffering, combating the climate crisis, and releasing valuable resources like water and land back for human use.

Nobell Foods is an example of how excellent science can create extraordinary impact through entrepreneurship. Inspired by their vision to create a radically more humane and sustainable food system, Fifty Years was proud to partner with Nobell in their pre-seed round and to deepen the partnership in their Series B, led by our friends at Breakthrough Energy Ventures, alongside Series A lead Andreessen Horowitz, existing investors Pear VC, Unovis, Germin8 Ventures, and AgFunder, and with new investor Footprint Coalition -- Robert Downey Jr.'s climate focused investment fund. At Fifty Years, helping great scientists and engineers become great entrepreneurs is our jam, and we’re looking forward to continuing to help Magi and team build a radically better food system for all -- people, animals, and the planet.

The calculations behind 1 gallon of milk requiring 6 pounds of feed:

1 gallon = 8.6 lbs

Milk composition: 3.3% protein, 3.4% fat, protein + fat total= 6.7%

Since conversion is based on protein and fat, protein and fat in 1 gallon of milk = 8.6 * 6.7% = 0.58lbs

Feed conversion ratio = 10, so we can calculate 1 gallon of milk requires 0.58 * 10 = ~6lbs of feed